Supply Chain

Infrastructure

The emergence of a liquid air or nitrogen economy, in which cryogenic liquids are widely used as an energy vector in transport and small-scale electricity generation, would require an extensive distribution network. It is one of the strengths of liquid air compared to some other potential energy vectors that this requirement is already broadly satisfied; thousands of tonnes of liquid oxygen and nitrogen are already distributed across the country every day.

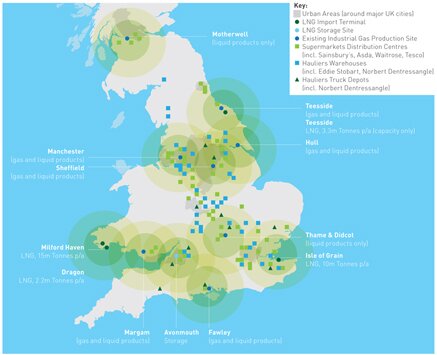

The map shows the location of existing industrial gas production sites; potential new production sites at LNG import terminals; urban conurbations; and the depots and distribution centres of some significant hauliers and supermarket chains, who may be early users of long-haul liquid air applications. Each production site is marked with a radius of 50 and 100 miles to show its potential delivery catchment area. It is clear that most of the UK is covered by existing or potential liquid air distribution.

From the analysis presented in our report ‘Liquid Air in the energy and transport systems’ we also conclude that:

• there already exists a well-established distribution network for cryogenic fluids in the UK and across the industrialised world;

• surplus production capacity in liquid nitrogen and the existing distribution network are more than adequate to supply the short to medium term fuel needs of an emerging ‘nitrogen economy’ (chapter 6 of the Full Report);

• specifically, the existing distribution infrastructure is more than adequate to supply the early development of on-site, return to base and some long-haul transport applications; and

• in the longer term, a mix of local production of liquid air and nitrogen, and centralised production combined with distribution by cryogenic tanker, is likely be able to satisfy any foreseeable demand.

Manufacturing and pathways to deployment

If liquid air as an energy vector benefits from a pre-existing ‘fuel’ distribution network (see Infrastructure) it may gain further advantage from the characteristics of the equipment that would run on it. Liquid air devices can generally be made substantially from existing components drawn from mature supply chains with few bottlenecks to hamper expansion. And unlike many other low carbon technologies – such as EVs – liquid air technologies require negligible rare earth metals and other scarce resources.

The Liquid Air Energy Storage system is made entirely from existing components drawn from the industrial gases and power generation industries. Key components such as compressors, cold boxes, heat exchangers, expansion turbines and generators are all available at scale from the global supply chain. A substantial proportion of a LAES plant could be also sourced from UK suppliers. A round table discussion of industry experts held at the Institution of Mechanical Engineers in March 2013 concluded that that if design, civil engineering and construction work were added to domestically produced components, around 50-60% of the value of a LAES installation could originate in the UK.

The round table also concluded there is no reason why the international supply chain should not deliver a target of 500MW of LAES capacity in the UK by 2020, or supply a potential UK market of 14GW by 2050. To achieve the earlier target, orders would need to start to be placed this year, but the current international supply chain is capable of delivering these levels of capacity without creating a bottleneck.

In transport, the Dearman Engine is a reciprocating (piston) engine that operates at near ambient temperatures, and as a result it is unlikely to offer many unfamiliar challenges to vehicle engine manufacturers. The most unfamiliar part of the system is likely to be the part exposed to cryogenic working fluid – liquid air or nitrogen. However, cryogenic technologies are mature and have been used in the industrial gas and LNG industries for decades.

There is a wide variety of materials suitable for use in cryogenic systems, including stainless steel, aluminium alloys, PTFE and polyethylene, which are plentiful and relatively low cost. This contrasts favourably with some of the materials required for other low carbon vehicle technologies, such as platinum in hydrogen fuel cells and lithium and neodymium in battery electric vehicles. In the short term it is expected that the Dearman Engine would have similar capital costs and embedded carbon to a conventional ICE, and significantly lower than EVs or FCVs.

The New Automotive Innovation and Growth Team (NAIGT) technology roadmap foresees the introduction of zero emissions vehicles in the 2020s, and we find liquid air vehicles could be developed in this timeframe. We also conclude that since the Dearman Engine could be used in heat hybrids, liquid air could extend the time before it becomes necessary to replace the ICE altogether by raising its efficiency and reducing emissions.