Comparing Explosion Risks: Liquid Air Technology vs. Oil production in Refinery - Ex Zones

In the quest for safer and more efficient energy storage and production methods, understanding the risks associated with different technologies is crucial. This article compares the explosion risks of liquid air energy storage (LAES) and oil production in refinery Ex zones, and highlights safety products like oil-in-water detectors that help mitigate these risks.

Liquid Air Energy Storage (LAES)

Risk of Explosion:

Nature of Liquid Air: Liquid air is primarily composed of nitrogen and oxygen, neither of which are flammable under normal conditions. This makes LAES systems inherently safer in terms of explosion risk compared to flammable substances.

Operational Safety: The primary risks in LAES systems are related to the extreme cold temperatures required to liquefy air and the high pressures involved. Proper insulation and pressure relief systems are essential to prevent accidents.

Oil production - Risk of Explosion:

Flammable Nature of Oil: Refineries handle large quantities of crude oil and its derivatives, which are highly flammable. The presence of flammable vapors and gases creates a significant explosion risk.

Ex Zones: These are classified areas where explosive atmospheres may occur due to the presence of flammable substances. Refineries often have multiple Ex zones, each requiring stringent safety measures to prevent ignition sources.

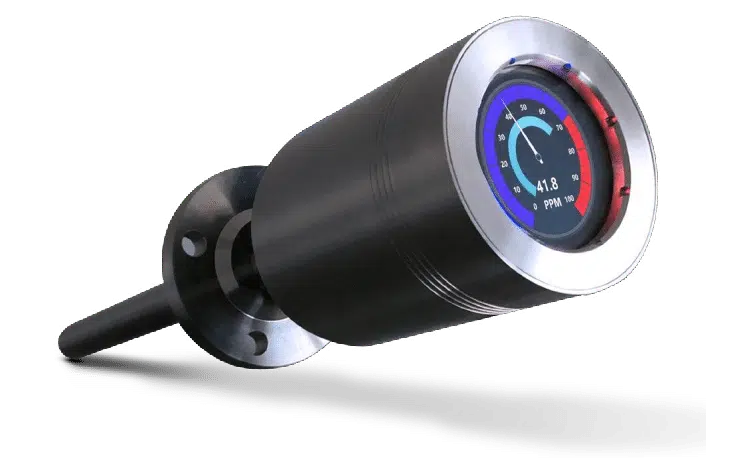

Safety Products - Oil-in-Water Detectors:

Function: These detectors are crucial in refineries to monitor and detect the presence of oil in water, which can indicate leaks or spills. Early detection helps in preventing potential fire hazards.

Examples: Products like the ATEX certified universal oil-in-water measurement and control GPP Controller are widely used in the industry for their reliability and accuracy.

Pressure Relief Valves:

Function: In both LAES and refinery systems, pressure relief valves are essential to prevent over-pressurization, which can lead to explosions.

Examples: Brands like Emerson and Fike offer high-quality pressure relief valves suitable for various industrial applications.

Gas Detection Systems:

Function: These systems detect the presence of flammable gases in the air, providing early warnings to prevent explosions in Ex zones.

Examples: Honeywell and Dräger offer advanced gas detection systems that are widely used in refineries.

Conclusion

While liquid air energy storage presents a lower explosion risk compared to oil in refinery Ex zones, both systems require robust safety measures to ensure safe operation. Utilizing advanced safety products like oil-in-water detectors, pressure relief valves, and gas detection systems can significantly mitigate these risks, ensuring a safer working environment.